IEC 60079 - Levels of Protection

Overview

Ex equipment and components have various letter suffixes in their description, for example Ex d. What do these mean? IEC (ATEX) letter codes or suffixes for electrical equipment specified by IEC 60079 describe levels of protection or protection type for equipment to be used in explosive gas and dust atmospheres. These are the specifications, construction, designs and features required for enclosures and components for use in an intended Ex Zone. System designers often have different options available to fulfill the technical requirements for a particular Ex Zone and may choose equipment that is most suitable or cost effective for the application. These IEC letter codes or suffixes include:

- ‘d’ - Explosion-Proof /Flameproof Enclosure

- ‘e’ - Increased Safety

- ‘i’ - Intrinsically Safe

- ‘m’ - Encapsulation

- ‘n’ - Non-incendive / non-sparking

- ‘o’ - Liquid Immersion

- ‘op’ - Equipment emitting Optical Radiation

- ‘p’ - Pressurization

- ‘q’ - Powder Filling

- ‘t’ - Protection by Enclosure

Most levels of protection types have 3 degrees of protection. These degrees ‘a’, ‘b’ and ‘c’ are analagous to the 3 Ex Equipment Categories ‘1’, ‘2’ and ‘3’ discussed on the previous page, with ‘a’ having the strictest requirements.

Of these Levels of Protection, the 5 most commonly used for sensors and power supplies for use in explosive atmospheres are summarised in the table below.

| Enclosure Definition |

Ga Cat 1 Zone 0 |

Gb Cat 2 Zone 1 |

Gc Cat 3 Zone 2 |

Da Cat 1 Zone 20 |

Db Cat 2 Zone 21 |

Dc Cat 3 Zone 22 |

Standard |

|---|---|---|---|---|---|---|---|

| Explosion-proof Flameproof |

da | db | dc | - | - | - | IEC 60079-1: 2014 |

| Intrinsic Safety |

ia | ib | ic | ia | ib | ic | IEC 60079-11: 2011 |

| Non-Arcing Enclosed |

- | - | nA nC |

- | - | - | IEC 60079-15: 2017 |

| Optical Radiation |

op is | op is op sh op pr |

op is op sh op pr |

- | - | - | IEC 60079-28: 2015 |

| Dust Ignition Protection |

- | - | - | ta | tb | tc | IEC 60079-31: 2022 |

General Requirements

IEC 60079-0:201715 (General Requirements) and 60079-46:201716 (Equipment Assemblies) apply to all categories of Ex equipment. Whilst IEC 60079-0 contains general requirements common to all Ex equipment, IEC 60079-46 is concerned with the design, construction and testing of the individual components inside Ex equipment assemblies, and may exclude exquipment wholly covered by a level of protection and equipment protection by pressurised enclosure ‘p’.

Each level of protection above is defined by its own IEC 600079 specification, which supplements and modifies the general requirements of IEC 60079-0, which is discussed below. The protection level specification takes precedence where a requirement conflicts with IEC 60079-0.

There are 6 Equipment Protection Levels (EPLs) for Ex equipment in non-mining explosive atmospheres defined by IEC 60079-0. For gas, these are ‘Ga’, ‘Gb’ and ‘Gc’. For dust, these are ‘Da’, ‘Db’ and ‘Dc’.

- Ga, Da - ‘very high’ level of protection: not an ignition source in normal operation, during expected malfunctions or during rare malfunctions

- Gb, Db - ‘high’ level of protection: not an ignition source in normal operation or during expected malfunctions

- Gc, Dc - ‘enhanced’ level of protection: not an ignition source in normal operation and may have additional protection to ensure it is not an ignition source during regular expected occurrences

IEC 60079-0 details a classification system for maximum surface temperatures for Group II electrical equipment.

| Temperature Class | Maximum Surface Temperature |

|---|---|

| T1 | 450°C |

| T2 | 300°C |

| T3 | 200°C |

| T4 | 135°C |

| T5 | 100°C |

| T6 | 85°C |

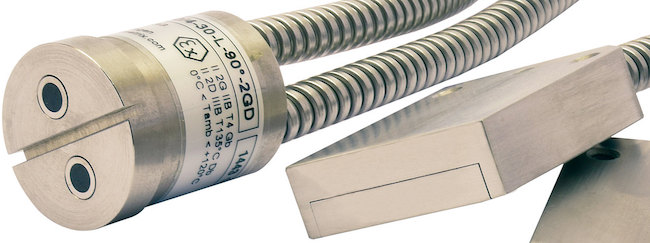

Flameproof Enclosure ‘d’

Flameproof and explosion-proof designs (‘d’) are defined by IEC 60079-1:201417, as an ‘enclosure in which the parts which can ignite an explosive gas atmosphere are placed and which can withstand the pressure developed during an internal explosion of an explosive mixture, and which prevents the transmission of the explosion to the explosive gas atmosphere surrounding the enclosure’.

Flameproof and explosion-proof designs rely on the physical enclosure to safely contain any ignition. All other classifications are concerned with explosion prevention. They are not completely sealed against the entry of flammable gases nor the exit of explosion, relying on specific mating of metal-to-metal surface to extinguish flames before they are able to leave the enclosure. Other flame barriers may be employed, e.g. flanged joints, which may allow gases but not flames to escape. Type 'd' enclosures are typically constructed of alumium, thick glass or stainless steel and are limited by size.

Intrinsic Safety ‘i’

Intrinsic Safety ‘i’, the construction and testing of intrinsically safe equipment for use in explosive atmospheres and for associated equipment intended for connection to intrinsically safe circuits which enter such atmospheres, is defined by IEC 60079-11:201118. IEC 60079-25:2020, for whole intrinsically safe electrical systems, takes precedence.

Intrinsically safe electrical circuits are low-energy designs incapable of releasing enough energy to cause an explosion in the surrounding explosive atmospheres. Type ‘i’ also applies to electrical equipment located outside the explosive atmosphere or protected by other means specified in IEC 60079-0, which are depended upon by electrical circuits in the explosive atmosphere.

Intrinsically safe equipment emplhas the advantage of being cheaper to manufacture and less bulky than employing flameproof enclosures.

Non-Sparking, Enclosed & Hermetically-Sealed ‘n’

Protection type ‘n’ applies to electrical equipment whereby in normal operation and in certain specified regular expected occurrences, it is incapable of igniting a surrounding explosive gas atmosphere. It is defined by IEC 60079-15:201719. This protection type includes two different protection levels, nA and nC, both of which are restricted to Category 3 equipment in Zone 2 (Gas) only, where the risk of simultaneous equipment malfunction and presence of explosive atmosphere is very low. The criteria for Intrinsically Safe devices are much stricter.

nA refers to non-sparking devices. Non-sparking devices are those constructed to minimise risk of arcs or sparks capable of causing ignition during normal operation, excluding the removal or insertion of components in a live circuit. Many different types of equipment would qualify as non-sparking without any special protective design being implemented.

nC refers to enclosed-break devices, hermetically-sealed devices non-incendive components and sealed devices. Enclosed-break devices incorporate electrical contacts that are made and broken and will withstand an internal explosion of a flammable gas or vapour entering it without suffering damage and without igniting the external flammable gas or vapour. Hermetically-sealed devices are constructed to prevent the ingress of the external atmosphere, where a fusion seal is employed, e.g. soldered, brazed, welded or through fusion of glass to metal. Non-incendive components have contacts for making or breaking a specified ignition capable circuit where no component of the contact mechanism is capable of causing ignition of the explosive gas atmosphere, without the requirement to exclude the atmosphere or contain the explosion, e.g. where the contacts extinguish any arc or spark. Sealed devices cannot be opened during normal operation and are sealed to prevent the entry of an external atmosphere.

Equipment Emitting Optical Radiation ‘op’

Optical equipment including lamps, lasers, LEDs and fibre optics is used for a variety of applications such as surveying, measurement, sensing and communications. Where optical radiation passes through explosive atmospheres, there may be a risk of explosion. The use of an absorber influences the risk of ignition. Most likely ignition mechanisms in practice include the heating up of surfaces or particles that absorb optical radiation; and a strong laser beam causing breakdown of gas or vapour, producing plasma and a shockwave, particularly if solid material is close to the breakdown point. Other less likely causes of ignition include thermal ignition of a gas where the optical wavelength matches the gas or vapour absorption band; and photo dissociation of Oxygen molecules by radiation in the UV wavelength range causing photochemical ignition.

Protection type ‘op’ defines the requirements, testing and marking of 380nm to 10µm optical radiation emitting equipment and components intended for use in explosive atmospheres, as well as equipment outside the explosive atmosphere or protected by another IEC 60079-0 Protection Type, which generates optical radiation that enters an explosive atmosphere. It is defined by IEC 60079-28:201520.

Where the source of optical radiation is inside an IP 6X or greater enclosure conforming to IEC 60079-0, unless optical radiation leaves such an enclosure, the ingress of optical radiation by absorbing outside targets need not be considered . However, targets within the enclosure shall always be considered.

Optical equipment is subjected to a formally documented ignition hazard assessment, in order to identify possible optical ignition sources that may arise and determine which any measures that may require implementing to reduce the risk of ignition.

There are three protection types for the prevention of ignitions by optical radiation in explosive atmospheres. Inherently safe optical radiation ‘op is’ is visible or infrared radiation incapable of producing sufficient energy under normal or specified fault conditions to ignite a specific explosive atmosphere (‘Intrinsically Safe’). Protected optical radiation ‘op pr’ is visible or infrared radiation confined inside optical fibre or other transmission medium under normal constructions (optionally with additional mechanical protection) where radiation cannot escape. Optical system with interlock ‘op sh’ is a system to confine visible or infrared radiation inside optical fibre or other transmission medium with provided interlock cut-off where in the event the confinement fails and the radiation beam becomes unconfined, to reliably reduce unconfined beam strength to safe levels within a specified time frame.

Items excluded from this protection type include ignition by ultraviolet radiation or absorption of radiation in the explosive mixture, explosive absorbers or absorbers that contain their own oxidiser, and catalytic absorbers.

Equipment Dust Ignition Protection by Enclosure ‘t’

Protection type ‘t’ applies to the requirements for design, construction and testing of electrical equipment and Ex components protected by enclosure and surface temperature limitation for use in explosive dust atmospheres and is defined by IEC 60079-31:202221.

Protection by Enclosure is where an enclosure cannot cause an ignition risk in explosive dust atmopheres by being tight enough to prevent the entry of explosive dusts into the enclosure. Some dust-proof enclosures may already qualify as Protection Type ‘t’ without the need for redesign. Other enclosure designs may not be suited for being dust-proof.

Explosive dust atmospheres according to type ‘t’ do not include the dusts of explosives, that do not require oxygen for combustion, or pyrophoric substances, which ignite instantly upon exposure to oxygen. Risks arising from the emission of flammable or toxic gas from the dust is not considered.

Additional protective measures are required where electrical equipment is in atmospheres containing combustible dust as well as explosive gas, either simultaneously or separately. Other environmental conditions may also require additional protection, e.g. water ingress or corrosion resistance, which should not interfere with the integrity of the protection type ‘t’ enclosure.

Protection Type ‘t’ is divided into three levels based on ignition risk in explosive dust atmospheres: ‘ta’, ‘tb’ and ‘tc’, corresponding to Ex Zones 20 to 22 respectively.

Type of protection ‘ta‘ includes the following requirements.

- Fault current - connection to a circuit having a prospective short circuit current (PSCC) of less than 10kA and labelled accordingly.

- Maximum surface temperature - measured on the external enclosure surfaces and internal components surfaces, with the maximum temperature used for the equipment marking.

- Over pressure - enclosure integrity under positive internal pressure of 2 kPa, except where gaskets or seals are physically constrained from moving, e.g. o-ring in a groove

- Dust exclusion - by enclosure

- Protective devices - a protection device is required where electrical equipment is capable of exceeding the maximum surface temperature previously tested. Protective devices are either integrated into the equipment or external and should be capacble or interrupting the maximum current of the circuit of the equipment. This includes equipment that contains a battery and a control device to prevent battery overheating as long as it prevents the equipment from exceeding the maximum surface temperature. One or more integral thermal protective devices is required, unless an integrated overcurrent protective device can be used to provide thermal protection instead (rated at no more than 170% of maximum rated current of the equipment). The response time of thermal protective devices shall be adequate for required overtemperature protection.

- Protection for arcing and sparking parts - Incorporated arcing and sparking parts shall have a supplementary enclosure inside the main enclosure, which shall meet the ‘tc’ standard (with exclusions), with the following additional requirements, including thermal endurance to heat and cold and resistance to light; COT of at least the lower specified ambient temperature and for non-metallic materials at least 20 K greater than the maximum service temperature; resistance to impact testing is required (not hot and cold); and IP6X is required.

Type of protection ‘tb‘ and ‘tc’ include the following requirements.

- Maximum surface temperature - measured on external enclosure surfaces with no dust layer under normal operating conditions.

- Over pressure - enclosure integrity under positive internal pressure of 2 kPa, except where gaskets or seals are physically constrained from moving, e.g. o-ring in a groove

- Dust exclusion - by enclosure